Reliability

Predictive Maintenance Company:

The efficiency asset reliability of your production hinges on the reliable operation of your equipment. Here at Cornerstone Mechanical, our specialization lies in mitigating unexpected and costly shutdowns in your production systems. One highly effective strategy for achieving this is the implementation of a routine vibration monitoring program. Through the utilization of such a program, we can proactively pinpoint issues before they escalate into failures, affording you the opportunity to procure necessary parts and schedule maintenance at your convenience.

A robust predictive maintenance program goes beyond resting on its laurels. For optimal outcomes, these predictive model programs encompass a myriad of methods and metrics to ensure that your equipment consistently operates at peak performance levels. In the realm of predictive maintenance services, Cornerstone Mechanical stands out by incorporating infrared thermography and oil analysis into our suite of PdM program options.

Given the inherent variability in maintenance costs among plants, a one-size-fits-all approach to predictive maintenance is impractical. At Cornerstone, we pride ourselves on crafting bespoke predictive maintenance programs tailored to suit the unique needs of your facility.

In the realm of predictive maintenance analytics, our commitment to customers extends beyond mere formulas. We recognize that each facility is distinct, prompting us to design custom PdM programs that align seamlessly with your requirements and operational nuances.

In instances where a singular intervention suffices, our adept team of predictive maintenance and repair technicians is at your service. Whether it’s off-route vibration testing or in-depth analysis software solutions for equipment exhibiting elusive problems, our team is equipped to provide comprehensive solutions. We extend both single-speed and variable-speed vibration testing, ensuring a thorough examination of your equipment’s health.

In essence, our suite of predictive maintenance services transcends the conventional, encompassing innovative methodologies and a commitment to meticulous maintenance planning. Trust Cornerstone Mechanical to be your reliable partner in sustaining your equipment performance and the optimal functionality of your equipment.

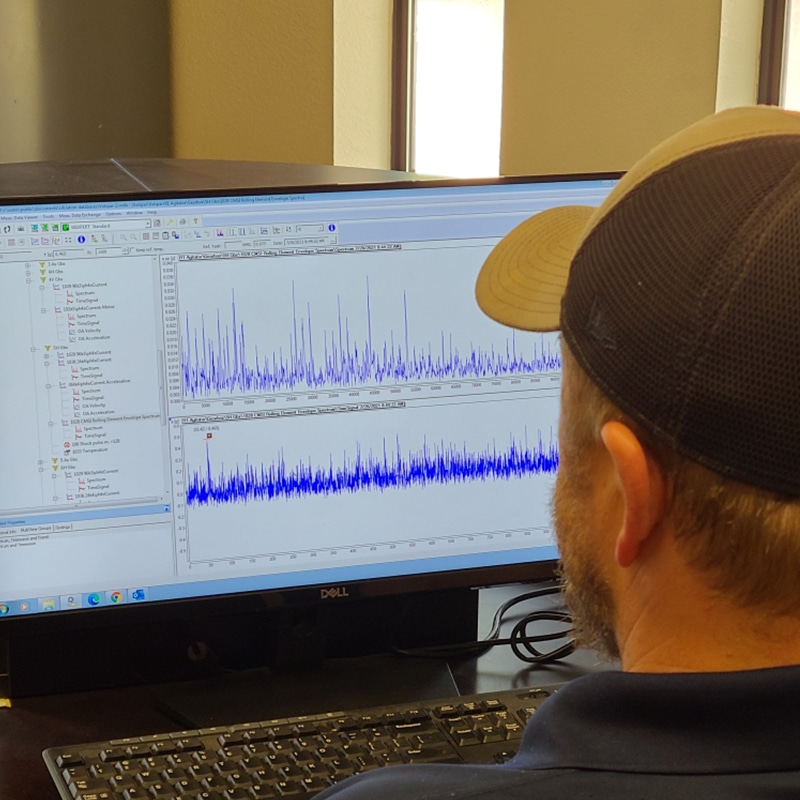

Predictive Maintenance Software: Vibration Monitoring & Analysis

The objective of a predictive maintenance program is to improve machinery reliability by identifying problems before they cause failures. If resources and costs have limited your company’s ability to maintain or even start an effective program, outsourcing maintenance operations can be the cost-effective solution.

At Cornerstone Mechanical, our predictive maintenance begins with vibration monitoring technology and analysis of historical data. Working together with you and your team, our expert mechanical technicians can give you confidence in your machinery for the foreseeable future and empower your team members to participate in future predictive maintenance efforts.

Vibration Monitoring and analysis has many vital steps. Here’s a brief (and by no means comprehensive) rundown of our process.

Waterfall vibration testing provides vibration data from 0% – 100% running speed for equipment controlled by a VFD system. This form of vibration testing can determine speeds at which equipment is operating on a critical, causing excessive vibration. Single-speed vibration testing is used to predict equipment failures and determine other possible issues with the unit, such as balance needs, looseness issues, bearing health, and more.

For both regular predictive maintenance and one-off maintenance, companies such as Cornerstone Mechanical can help.

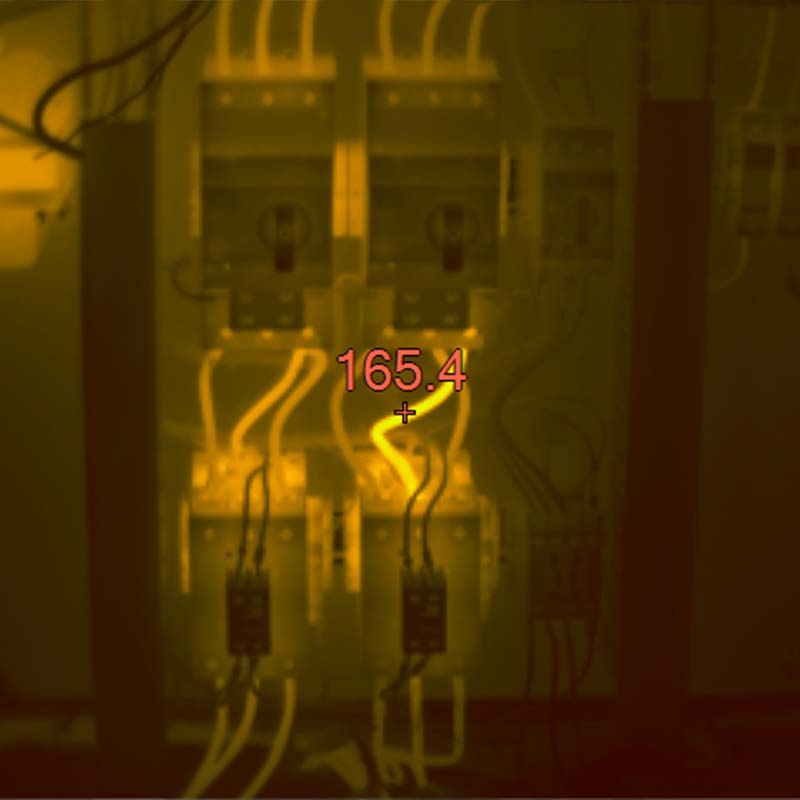

Infrared Thermography

Cornerstone Mechanical has added infrared thermography to our predictive maintenance and asset management toolbox. Using an infrared camera, our certified technicians can now monitor equipment performance and test your electrical panels for excessive heat that could be caused by loose or overly tightened wire connectors. We can also test your machinery for problem areas like overheated bearings. Together with our vibration monitoring and analysis services, infrared thermography can reveal pain points in your machinery to help you plan for smoother, undisturbed future operations.

At Cornerstone Mechanical, we know that there’s more than one way to forestall future machine and equipment failures. In the pursuit of consistently high performance, we’ll stop at nothing and embrace every method. A good predictive maintenance program includes more than one way to take downtime and ensure your equipment is performing at optimum levels.

Predictive Maintenance With Cornerstone Mechanical

The best emergencies are the ones that never happen. With Cornerstone Mechanical’s cutting-edge, predictive maintenance technologies and services, you can identify problem areas and problem parts long before they reach a critical state of failure. The more you know about your machinery, the further into the future you can see.

Proudly serving communities in Northeast Texas, including Dallas and Fort Worth, our predictive maintenance services are here for you before the worst happens. To schedule predictive and preventive maintenance now, call Cornerstone Mechanical, today at 214-570-9498.