Precision is critical to maintaining equipment performance, safety, and efficiency in industrial environments. Balancing and laser alignment are critical practices that optimize rotating machines’ functionality, reducing wear, minimizing vibration, and preventing costly breakdowns. From aviation to water treatment facilities, these techniques are essential for extending equipment life and maintaining productivity across various industries.

Here, we’ll explore the importance of these techniques and how they benefit industrial operations. At Cornerstone Mechanical, we understand the demands of these specialized fields and provide reliable balancing and alignment services to support our clients in Northeast Texas.

The Importance of Proper Balancing in Rotating Equipment

Proper balancing is essential for maintaining the integrity and longevity of rotating machinery. Equipment imbalance occurs when rotating components, such as fans, pumps, or turbines, have uneven weight distribution, causing vibrations that can stress bearings, seals, and other critical parts. Over time, this can lead to excessive wear and tear, increasing the likelihood of mechanical failures, costly repairs, and even unscheduled downtime. By addressing imbalances, industrial operators reduce maintenance costs and improve safety, as vibrations can create hazardous conditions for workers nearby.

Unbalanced machinery also consumes more energy, as motors and other components work harder to compensate for the imbalance. This increased energy demand can lead to overheating and reduce overall system efficiency, driving up operational costs. Regular balancing procedures help reduce these issues, supporting the equipment’s performance and sustainability. In industries like food processing and manufacturing, where continuous operation is crucial, proper balancing ensures uninterrupted production, enhancing reliability and product consistency.

At Cornerstone Mechanical, we specialize in dynamic balancing, a method that adjusts the balance of rotating equipment while it’s operating, achieving precise, real-time adjustments. By utilizing advanced balancing equipment, our team can measure and correct imbalances quickly, minimizing operational interruptions. This approach is particularly beneficial in high-demand settings, like paint manufacturing or semiconductor production, where equipment runs continuously, and any downtime can impact output. Proper balancing is a proactive measure that helps industries protect their investments and optimize performance for years.

Benefits of Laser Alignment for Industrial Machinery

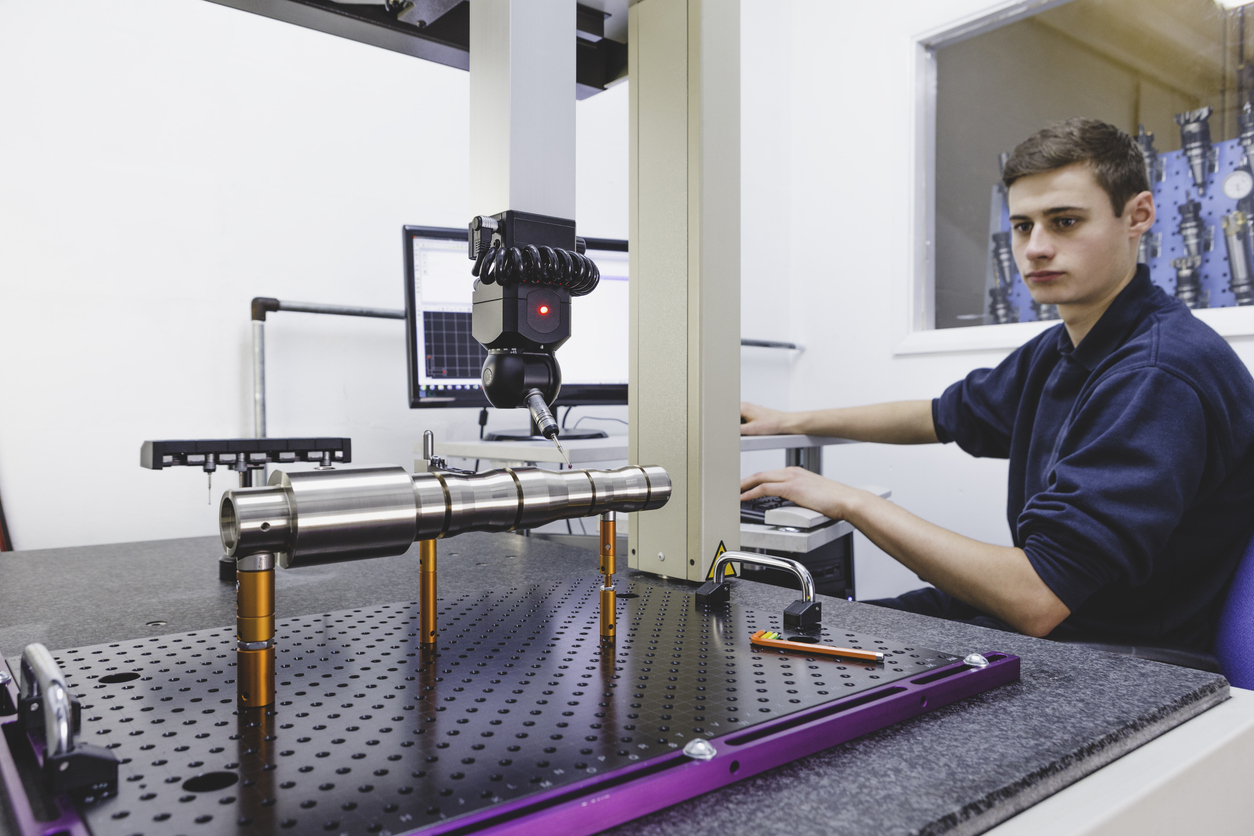

Laser alignment offers unmatched accuracy and efficiency in aligning industrial machinery, significantly improving the performance and lifespan of rotating equipment. Traditional alignment methods involving manual measurements can be time-consuming and lack precision.

Laser alignment, on the other hand, uses advanced laser technology to achieve precise alignment in a fraction of the time. This technology is highly effective in identifying misalignment, which is a common issue in industries with high-speed rotating machinery, such as roofing materials production and semiconductor manufacturing.

Misalignment can lead to uneven wear on components, causing increased vibration and stress on motors, bearings, and shafts. Over time, this results in costly repairs and reduced equipment life. With laser alignment, even minor misalignments are detected and corrected, which helps maintain optimal performance and significantly lowers maintenance costs. Laser alignment also enhances safety by ensuring that machinery runs smoothly and minimizing the risk of unexpected equipment failure or part breakdown, which can lead to hazardous conditions.

For industries like aviation, where precision is paramount, laser alignment provides peace of mind that equipment operates within exact tolerances. At Cornerstone Mechanical, we utilize state-of-the-art laser alignment tools that deliver precise, reliable measurements so machinery functions seamlessly. Our laser alignment services reduce downtime, lower operational costs, and extend the service life of critical machinery, making them an invaluable part of equipment maintenance across various industrial settings.

Tools & Technology Used by Cornerstone Mechanical

Cornerstone Mechanical utilizes specialized tools and technology to achieve precise alignment and balancing, catering to industries with rigorous performance standards. Our laser alignment tools are designed to provide high-accuracy real-time data, allowing our team to identify alignment issues and correct them swiftly.

These tools use laser beams to measure the alignment of components with minimal margin for error, enabling a level of precision that manual methods can’t achieve. By employing this advanced technology, we ensure that our clients’ equipment runs optimally and meets industry-specific standards.

In addition to laser alignment tools, we rely on dynamic balancing machines that adjust rotating equipment while it operates. This capability is particularly advantageous in environments with continuous operations, like food processing or water treatment facilities, where minimizing downtime is crucial. Dynamic balancing technology allows immediate adjustments, correcting imbalances in real time to improve machinery efficiency and safety. Our team is trained to use these tools effectively and provides a thorough, reliable service that addresses even the most complex alignment needs.

Cornerstone Mechanical’s commitment to using top-tier technology in alignment and balance translates to high-quality service for our clients. With specialized tools and trained technicians, we offer solutions that protect valuable machinery, enhance productivity, and help businesses operate confidently. From advanced laser alignment systems to dynamic balancing machines, our technology investments enable us to deliver precision and performance in every project.

Why Professional Alignment & Balancing Isn’t a DIY Job

Balancing and laser alignment requires precision, specialized tools, and industry-specific expertise that surpass standard in-house capabilities. Attempting these tasks without the right equipment and experience can lead to inaccurate results, quickly impacting machine performance and safety.

The Risks of In-House Alignment Attempts

Without specialized tools, in-house teams may struggle to achieve the precise alignment needed for optimal performance, leading to increased wear, energy inefficiency, and unexpected breakdowns. Misalignments, even if minor, place additional stress on components, shortening equipment life and heightening the risk of failure.

Also, without proper training, there’s a greater chance of missing subtle issues that only professional equipment can detect. This makes it critical for organizations that depend on rotating machinery to invest in expert alignment services from Cornerstone Mechanical.

We offer the expertise to align and balance rotating machinery properly, preventing issues like excessive wear, energy inefficiency, and breakdowns. With our professional services, businesses gain accurate, reliable alignment that maintains equipment integrity, enhances safety, and saves on costly repairs and downtime.

Find Precision Alignment Experts in Northeast Texas at Cornerstone Mechanical

For precise laser alignment and balancing services in Northeast Texas, trust Cornerstone Mechanical. Call us at 214-570-9498 today or reach out right here to learn more about our tailored services and how we can enhance the efficiency and longevity of your equipment.