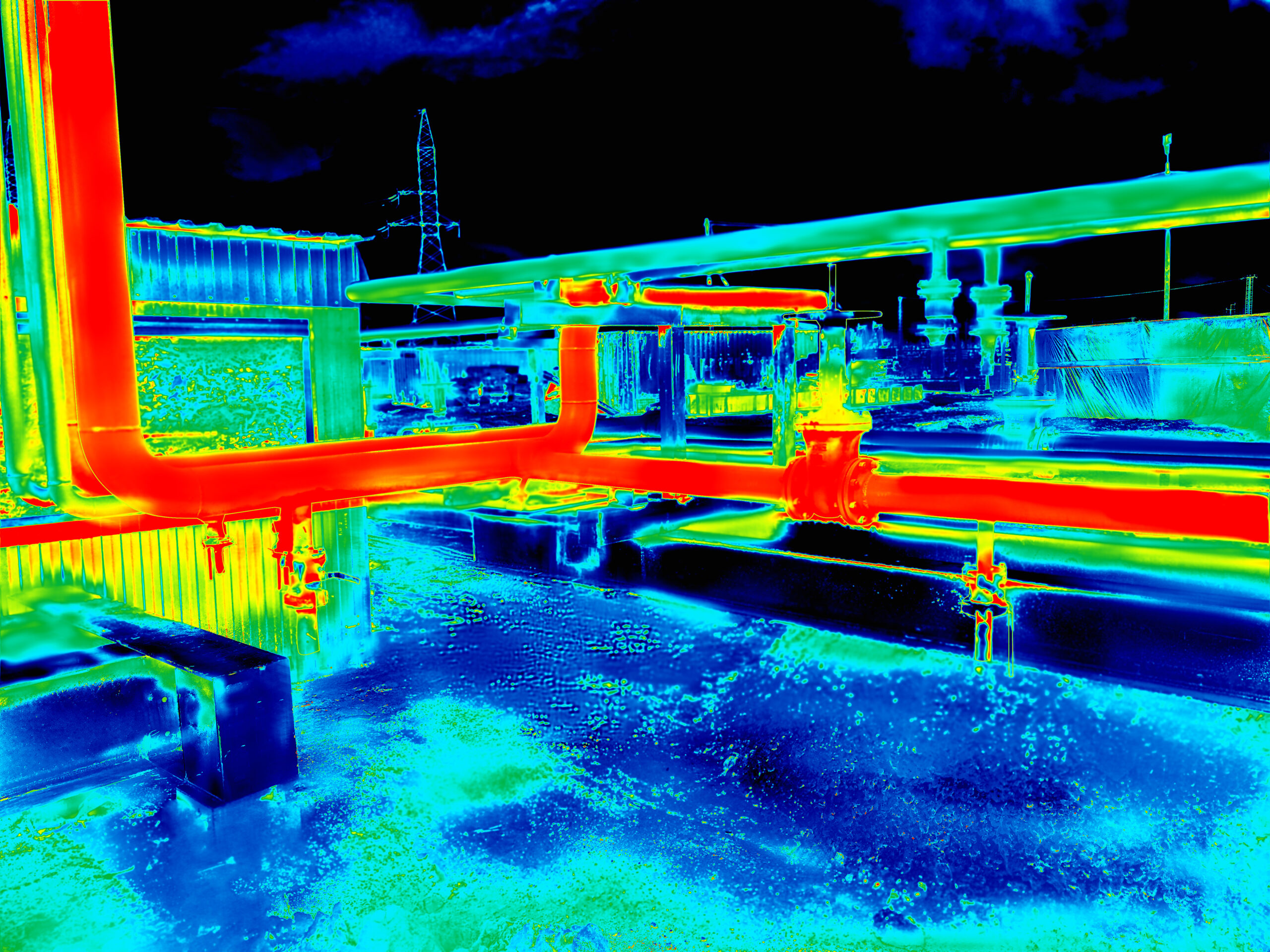

Infrared Thermography: A Key Tool in Predictive Maintenance

Predictive maintenance has revolutionized the manufacturing industry by allowing businesses to anticipate and address potential equipment failures before they occur. This proactive approach reduces downtime, enhances safety, and improves overall operational efficiency. At the core of predictive maintenance is a…